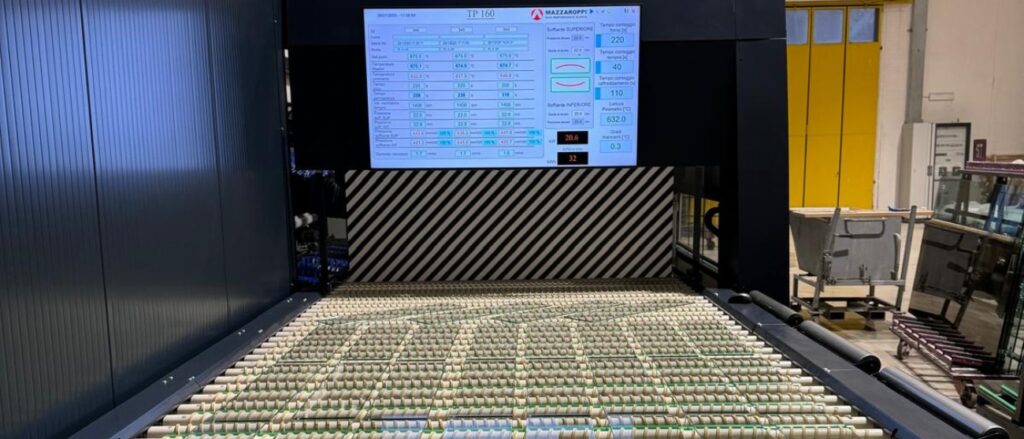

At the beginning of 2025, we completed a significant installation in Lombardy: a TP Compact oven for the family-run company Vetreria Aurora in Flero (BS).

We are pleased to share this experience as it demonstrates the potential of Mazzaroppi’s new patented Efficiency 5.0 software.

Who is Vetreria Aurora?

Founded and run by the Rossi family, Vetreria Aurora is a dynamic, quality-conscious company based in Brescia with 30 years’ experience in glass processing. They specialise in processing for the furniture, art and construction sectors. For them, installing our TP Compact is an important step towards more efficient and sustainable production.

The Mazzaroppi team was supported by our valuable local sales partner, Si.ste Trading, for the sale and installation of the furnace.

Why did Vetreria Aurora choose the TP Compact furnace?

The deciding factor in Vetreria Aurora’s purchase of the furnace was its low energy consumption.

Thanks to Mazzaroppi’s new patented Efficiency 5.0 software, we can actually keep peaks to a minimum.

Efficiency 5.0:

- Drastically reduces the electrical installation required.

- Allows you to select peak power depending on the production type.

- Maximises consumption during all phases of the cycle.

- Ensures even more intelligent and uniform heating of the plates.

All Mazzaroppi furnaces with Efficiency 5.0 improve productivity and hardening quality, with energy consumption up to 70% lower than competing products.

The Mazzaroppi solution

Vetreria Aurora has chosen the TP Compact oven, a 1600×3600 mm convection model that is perfect for handling all types of glass, including low-e. The TP Compact is a high performance, compact oven that can be easily installed and does not require a wall to lean against, thus eliminating the need for costly masonry work.

However, it is the oven’s technological heart that really sets this project apart: our new patented Efficiency 5.0 software.

Thanks to this innovation, we were able to guarantee the high performance typical of Mazzaroppi ovens while keeping the maximum installed power to a minimum at just 180 kW.

Despite the reduced power, Vetreria Aurora’s TP Compact can still temper glass from 4 to 19 mm thick.

There was also no need to install a dedicated electrical cabinet, which was advantageous for the company. Currently, Vetreria Aurora’s TP Compact is the only oven in Lombardy that operates without a dedicated electrical cabinet.

Which tempering furnace can elevate your work without increasing your energy consumption?

Call us today to find out more.