An inefficient transition between different glass formats can cause real problems during the tempering process. It’s not just a matter of wasting time; unfortunately, there are real risks to the success of the process, which could be irreparably compromised.

So, how can these problems be avoided? The answer lies in choosing a glass tempering furnace that is optimised for smooth and fast format changes.

Here are the main risks that can be avoided with this type of furnace.

The management problems of a format change that is too slow…

First, let’s address the critical issues related to your production rates. As you are aware, if a cog jams, it can disrupt all the programmes in your production ‘machine’.

If this problem is not an unexpected event, but rather a recurring risk — as is the case with a format change that is too slow — you will lose time and money with every hardening cycle.

Increased downtime

A slow format change reduces productivity, causing unnecessary machine downtime and slowing down overall production.

Need to temper only in series

If the format change takes too long, you cannot switch from one type of glass to another as and when required, but must schedule long series of identical glass tempering.

This reduces your flexibility.

Energy waste

While waiting to switch from one format to another, furnaces often remain on but are not producing, resulting in increased energy costs. If you find yourself in this situation all the time, it will certainly be noticeable on your bill.

Risk of operational errors

Working times that are too long can lead to carelessness or errors in parameter adjustment, which can result in defects in the tempered glass.

… and technical problems

The speed at which the format changes also has a direct impact on the quality of glass tempering.

Thermal unevenness

A slowdown in format change can result in the glass being heated unevenly. This increases the risk of spontaneous breakage or fragmentation defects.

Glass deformation

If the furnace is left inactive or on standby for too long between formats, and the glass is not heated or cooled evenly, it can become deformed, for example by warping or undulating. These imperfections affect the appearance, flatness and functionality of the final product, for example softening or optical distortion (e.g. distorted reflections on the glass).

Increase in surface defects

Inefficient format change management can introduce surface defects, such as scratches or inclusions, which act as trigger points for breakage during or after tempering.

Risk of accidents

If the glass has not been tempered correctly, it is more likely to break and endanger the safety of operators. Accidental breakage of a glass sheet can pose a serious danger to nearby workers.

A fast and safe changeover is essential to guarantee you a smooth and flexible production of your tempered glass, as well as to contain the consumption of your furnace.

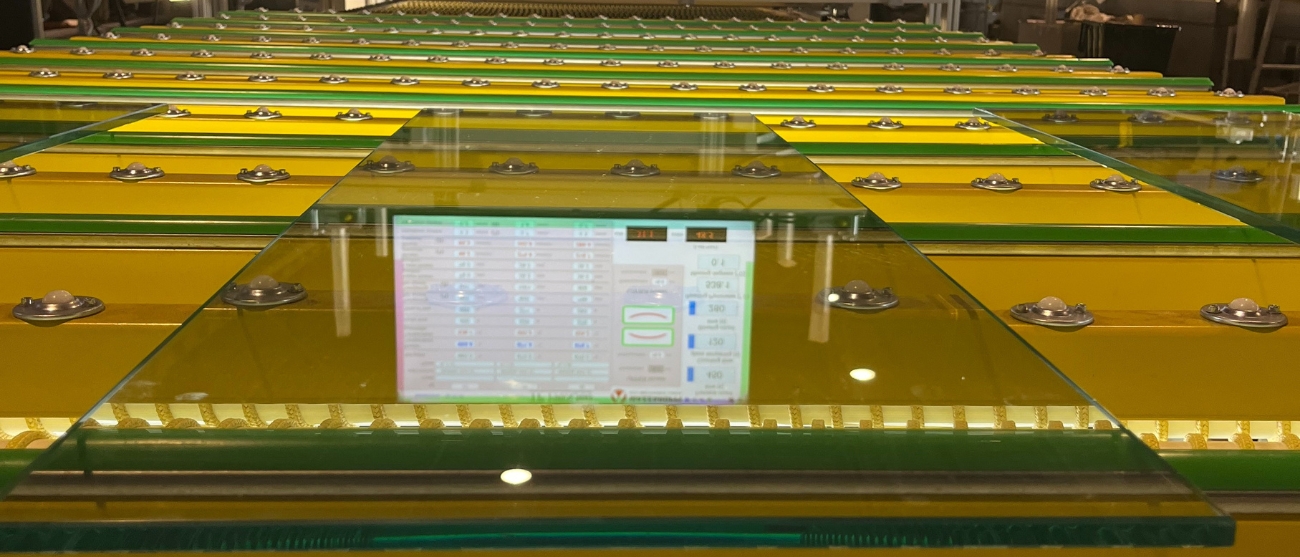

Mazzaroppi’s ovens are the most energy-efficient on the market because they can assure you excellent tempering with consumption up to 70 percent lower than competing solutions – thanks to proprietary technologies designed and manufactured to optimize tempering yield and efficiency.

The M Adapt – Thickness Change Responsive System, for example, is a technology that ensures responsive thickness changes, eliminating unproductive waiting times. Mazzaroppi furnaces adapt quickly and flexibly to the production needs of glassworks and companies, enabling consecutive changes to the thickness of the batch or the type of glass without any waiting time.

The principle behind Mazzaroppi technology is simple: the furnace should adapt to the production needs of the moment by automatically changing the process parameters, rather than the company having to adapt to the furnace’s functionality.

This eliminates waiting times for format changes and reduces unproductive energy costs.

Would you like to know how much you could save with a truly energy-efficient glass tempering furnace?

Request Mazzaroppi’s free Energy Saving Check and we will show you how to guarantee up to 70% lower energy consumption than competing solutions, while avoiding material and time wastage and always achieving the best possible results.

Call us to find out more.