Every glass tempering furnace requires energy. However, not all furnaces have the same consumption levels. It is possible to reduce a furnace’s energy requirements without compromising the quality of the tempering process.

Peak power consumption control is therefore key to determining a system’s true level of efficiency.

This is why Mazzaroppi has developed M Efficiency 5.0: patented software designed to significantly reduce electrical power requirements during production, without compromising tempering quality.

This technology has the potential to transform the way companies organise their production.

The impact of energy peaks in glass tempering

During the tempering cycle, the glass is heated rapidly to temperatures above 600 °C. This requires the heating elements to be activated intensely, particularly in the initial phase. The furnace therefore quickly reaches its maximum available power, generating high absorption peaks.

The problems associated with these peaks are real:

- higher energy bills, due to more expensive consumption bands,

- the need for dedicated electrical substations or high installed power,

- risks of instability in the company’s electrical network, especially in multi-service environments.

Without an intelligent peak regulation system, consumption can skyrocket. M Efficiency 5.0 was created precisely to address this issue, working efficiently to limit energy peaks and make the oven more sustainable.

How does M Efficiency 5.0 work?

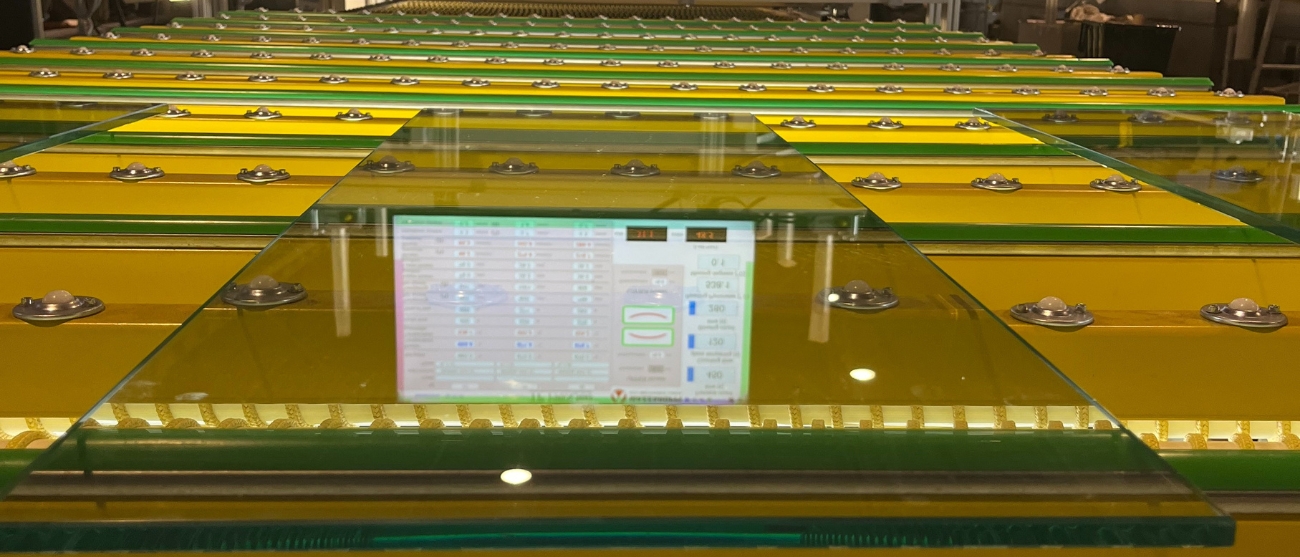

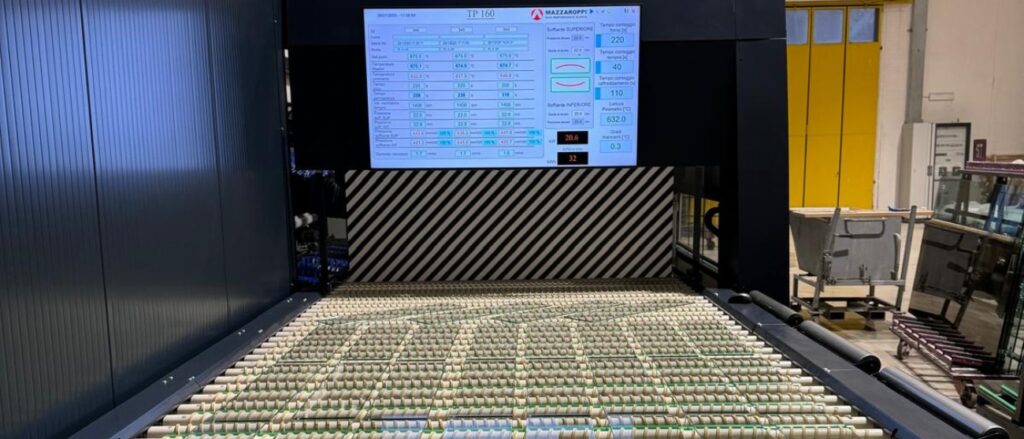

It is patented software that is integrated into Mazzaroppi glass tempering furnaces.

It operates on the principle of using only the necessary amount of energy, in the necessary place and at the necessary time.

Mazzaroppi’s M Efficiency 5.0:

- Drastically reduces the electrical system required, even eliminating the need for a dedicated electrical cabinet.

- Allows you to select the peak power based on the type of production.

- Optimises consumption during all phases of the cycle, enabling tempering with as little as 180 kW.

- Ensures smarter, more uniform heating of the sheets for improved tempering quality and reduced consumption.

The result is a more linear energy consumption profile that is free of unnecessary peaks and therefore much more economical and manageable. This means that Mazzaroppi furnaces consume up to 70% less energy than competing solutions.

This is a system designed for flexible production.

Thanks to M Efficiency 5.0, glassworks and other companies can achieve significant energy savings, even when working with glass of different types, thicknesses and sizes.

Mazzaroppi furnaces are versatile thanks to their integration with other proprietary technological solutions developed by the company, such as:

- M Start&Stop JIT Ignition: Reaching the operating temperature in 1 hour, allowing the furnace to be switched off at the end of the shift and restarted in less than 30 minutes, eliminating unproductive consumption.

- M OptiConvection: the optimised convection process that uses hot air only in the portion of the furnace where the glass is located, adapting to the percentage of space occupied in order to achieve superior tempering quality with significantly lower consumption.

- The M Adapt Thickness Change Responsive System is the technology that ensures responsive thickness change, reducing unproductive waiting times to zero. This makes Mazzaroppi furnaces fast and flexible when it comes to changing the thickness of the batch and the type of glass. This can be done consecutively and without waiting times. This greatly increases company productivity because it frees glassworks from having to temper identical glass formats consecutively, making production more flexible.

The combination of this technology and others makes every Mazzaroppi furnace an excellent production tool and an ally in cost management, process optimisation, and compliance with the most advanced energy standards.

Would you like to learn more about our new, patented M Efficiency 5.0 software?

Call us with no obligation to ask your questions.